Seal the gap between piston and cylinder, prevent gas axial leakage, ensure the closure of cylinder volume chamber, achieve the purpose of compressed gas.

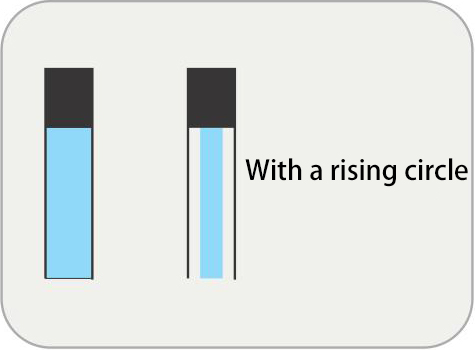

Type: YO-PR01

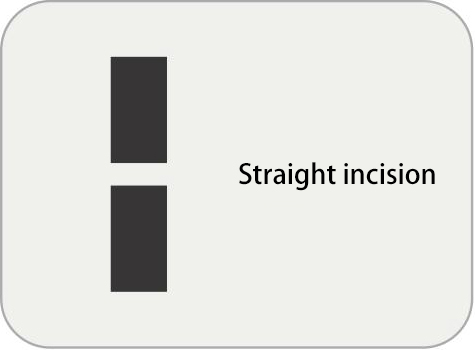

Usage: Usually used for aluminium piston without hardening treatment, which can reduce the wear of aluminium piston caused by the rotation of ringFeature: 1. Single straight incision design, high incision strength, not easy to break

2. Easy to install

Type: YO-PR02

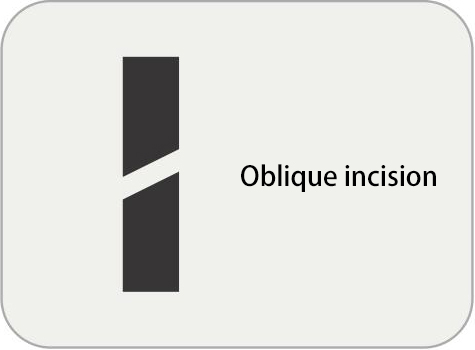

Usage: Most widely used, but not recommended for aluminium piston

without hardening treatmentFeature: 1. Inclined notch design, better sealing performance than straight notch

2. Easy to install

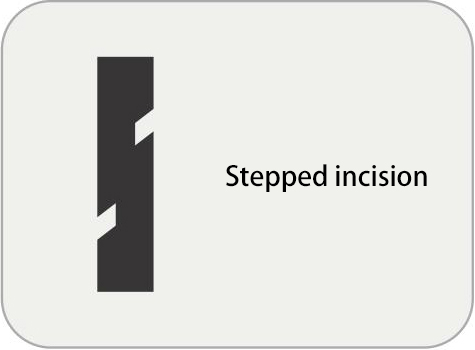

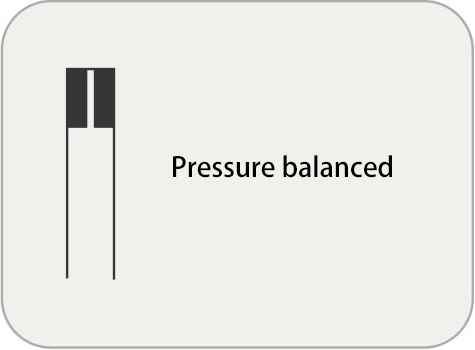

Type: YO-PR03

Usage: Suitable for medium and high voltage Feature: 1. Pressure balanced design, effectively reduce the wear of the lower ring under high pressure

2. Easy to install

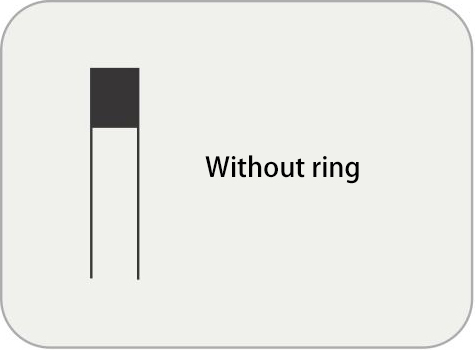

Type: YO-PR04(Brittle materials)

Usage: Two-lobe design, often used in small cylinder diameter Feature: Inclined incision design, less leakage than straight incision

Type: YO-PR05

Usage: mostly used for small cylinder diameter, medium and high pressure gas Feature: 1. Two-lobe design, brittle wear-resistant materials can be used in small cylinder diameter

2. Pressure balance design can reduce ring wear and prolong service life

3. Inclined incision, relatively small leakage

Type: YO-PR06

Usage: Used in light gas Feature: 1. Design of lapping incision, high sealing efficiency

2. Easy to install

Type: YO-PR07

Usage: Used in small diameter, high pressure, light gas Feature: lapping incision design, high sealing efficiency

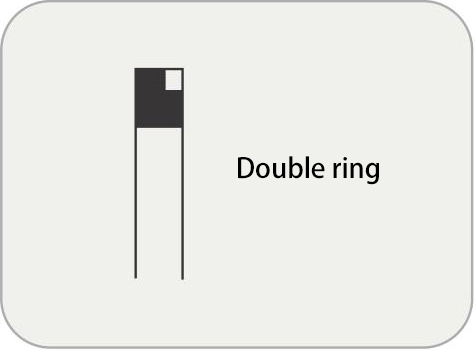

Type: YO-PR07

Usage: For low pressure, light gas Feature: 1. Double-ring structure, L-ring + rectangular ring design

2. Incisions staggered, high sealing efficiency